The Number Of Slots Per Pole Should Be

- For A 5 Kw Dc Motor The Number Of Slots Per Pole Should Be

- The Number Of Slots Per Pole Should Be Paid

- The Number Of Slots Per Pole Should Be Replaced

- The Number Of Slots Per Pole Should Bet

- The Number Of Slots Per Pole Should Beams

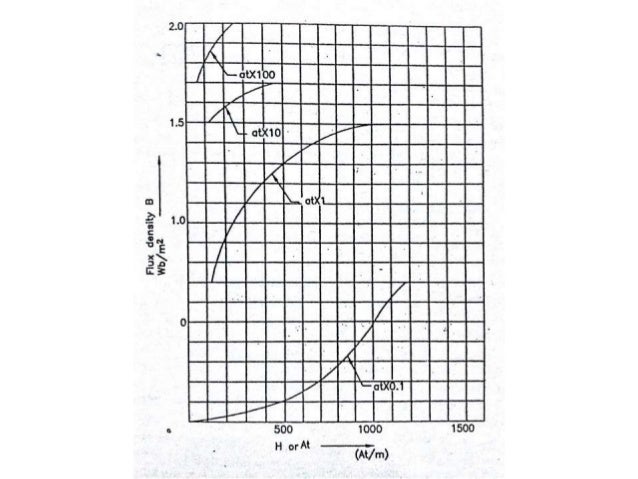

Most (8) pole motors use (24) slots but an (18) slot stator is superior. Another excellent low cost low cogging (8) pole design would be an (8) pole (9) slot motor. A ripple-voltage component with a peak-to-peak value of five to six per cent of the output voltage is typical for brushed tachogenerators. The ripple voltage can be reduced, by the use of a moving-coil configuration which has a high number of coils per pole, this minimises the ripple voltage to around two to three percent. This shows a three-phase, two-pole winding in the twelve slots. Such a winding would have two slots per pole per phase. One of the two coils of phase A would be wound in slots 1 and 7 (six slots apart). 1 2 3 4 5 6 7 8 9 10 11 12 A A C’ C’ B B A’ A’ C C B’ B’ A C’ C’ B B A’ A’ C C B’ B’ A.

Assignment—5

Sub : Electrical Engg (EEE-101/201)

B.Tech. First year

The distribution factor Kd for a given number of phases is dependent only on the number of distributed slots under a given pole. It is independent of the type of the winding, lap or wave or the number of turns per coil, etc. The distribution factor decreases as the number of slots per pole increases.

(Direct Current Generator)

Formula:

Eg = for LapWinding ; Eg = for Wave WindingEg = Vt + Ia ra + 2Vb ; Ia =Ish + IL ; Ish = ; IL = ; PL= Vt .IL

Where Eg = Generated emf, φ = Flux per pole, Z = total no. of conductors

N = Speed in rpm, P = no. of poles, Vt = terminal voltage, Ia = armature current, IL = Line(load) current , Ish = Shunt field current, Rsh = Shunt Field resistance , Vb =Brush drop, P L= Poweroutput , RL = Loadresistance

1. A 4 - pole, wave generatedarmature in a dc generator has 51 slots with 12 conductors per slot. It isdriven at 900rpm. If the useful flux per pole is 25mWb, calculate the value ofthe generated emf. Ans: 459V

2. An 8 -pole, dc generator running at 1200 rpm and with a flux of 25mWb per polegenerates 440V. Calculate the numbers of conductors, if the armature is i) lap wound ii) wave wound.

Ans: i) 880 ii) 220

3. A 4-poledc shunt generator has a useful flux per pole of 0.07Wb. The armature has 400lap wound conductors, each of resistance 0.002 Ω ohm and is rotated at 900 rpm.If the armature current is 50 A, calculate the terminal voltage.

Ans: 417.5V

4. An 8-pole dc generator has 500armature conductors and a useful flux per pole of 0.05Wb. i) What will be theemf generated, if it is lap-connected and runs 1200 rpm? ii) What must be the speed at which it is tobe driven to produce the same emf, if it is wave wound?

Ans: i) 500V ii) 300 rpm

5. A separately excited 4 - pole, 900rpm wave wound dc generator has an induced emf of 240V at rated speed and ratedfield current. When connected to a load, the terminal voltage is observed to be200V. If the armature resistance is 0.2 Ω and the flux per pole is 10 m Wb,compute the armature current and the number of conductors.

Ans 200A, 800

6. A 4- pole dc shunt generator with lapconnected armature has field and armature resistance of 80 Ω and 0.1 Ωrespectively. It supplies power to 50 lamps rated for 100Volts, 60 Watts each.Calculate the armature current and the generated emf by allowing contact dropof 1V per brush.

Ans: 105.12V

7. A 4- pole dc shunt generator witha shunt field resistance of 100 ohm and armature resistance of 1 Ω has 120 waveconnected conductor in its armature. The flux per pole is 60mWb. If a loadresistance of 20Ω is connected across the armature terminals and armature isdriven at 1000 rpm, calculate the voltage across the load terminals.

Ans: 226.41Volts

8. Find the flux per pole of a 50 KW dc shuntgenerator having 4 poles and a lap wound armature with 380 conductors. Themachine is run at a speed of 800 rpm and generates 460V. Resistance of thearmature and the shunt field are 0.5 Ω and 300Ω respectively. Find the currentflowing in the armature at the full load and the terminal voltage.

Ans: Ф = 0.0908Wb, Vt = 396.2V, Ia = 127.43 A

9. A 4 pole lap connected armature ofa dc shunt generator is required to supply the following loads: i) 5KW geyser at 250 V dc ii) 2.5 KW lightingload at 250VDC. Generator has an armature resistance of 0.2 Ω and a fieldresistance of 250 Ω. Armature has 120 conductors in slots and runs at 1000 rpm.Allowing 1V per brush for contact drop and neglecting armature reaction,find i) flux per pole ii) current per parallel path.

Ans: i) 0.129 Wb ii) 7.75 A

10. A 200 KW, 600 V DC, 6 pole dcshunt generator has an armature with 18 slots per pole. It has a simple lapwinding with 4 conductors per slot. The armature and shunt field winding hasresistance of 0.1 Ω and 50 Ω respectively. The flux per pole is 0.07 Wb.Calculate the speed at which it is to be driven for rated load operation.

Ans: Eg = 634.53V , N= 1259 rpm

-----------------------------------------------------------------------------------

DIRECT CURRENT MOTOR

Formula:

Eb = for Lap winding; Eb = for Wave winding

Vt = Eb + Iara + 2Vb; Ia = IL - Ish ; Ish = ; PL= Vt .IL

Where Eb =Back emf, φ = Flux per pole, Z = total no. of conductors

N=Speed in rpm, P = no. of poles, Vt = terminal voltage, Ia = armature current, IL = Linecurrent , Ish = Shunt field current, Rsh= Shunt Field resistance , Vb = Brushdrop, P L= Power output

1. A DC shunt motor operating at 200Vdc has armature resistance of 0.5 Ω. If its armature current is 25 A, calculatethe back emf. Ans: 187.5 V

2. A 4- pole lap wound armature DCshunt motor has flux per pole of 25 mWb. The number of armature conductor is200. The motor draws armature current of 20A when connected across a 200V dcsupply. Calculate the back emf and the speed of the motor if the armatureresistance is 0.4 Ω. Ans: 192V, 2304 rpm.

3. A 4- poles, lap wound armature DCshunt motor draws 40A armature current. The armature conductor is 400. Flux perpole is 20mWb. Calculate the gross torque developed by the armature of themotor. Ans : 50.83 Nm.

4. A 4 - pole lap wound DC motor has480 conductors. The flux per pole is 24mWb and the armature resistance is 1 Ω.If the motor is connected to a 200V dc supply and running at 1000 rpm on noload, calculate

i) backemf ii)armature current iii)power output iv) lost torque

Ans: i) 192V ii) 8A iii) 1536W iv) 14.67 Nm

5. A 60HP, 110VDC series motor has armaturewinding resistance of 0.18 Ω and series winding resistance of 0.13 Ω. The ratedcurrent is 45 A at 450 rpm. Determine the speed of the motor when the motorcurrent is 50 A. Ans: 398.6 rpm

6. A 200V DC shunt motor has armatureresistance 0.2 Ω and shunt field resistance 200Ω. If the no load and the fullload current drawn by the motor are 5A and 40 A respectively then calculate thefull load speed, assuming that the no load speed is 1000 rpm. Ans: 964.85rpm

.7. A 250 V DC shuntmotor having armature resistance of 0.25 Ω carries an armature current of 50 Aand runs at 750 rpm. If the flux is reduced by 10 %, find the speed. Assumethat the torque remains the same. Ans: 828.46 rpm.

8. A 500 V DC shunt motor runs at a speed of 250 rpm whennormally excited and taking a armature current of 200 A. The resistance ofarmature is 0.12 Ω. Calculate the speed of the motor when the flux is reducedto 80% of the normal value and the motor is loaded for an armature current of100A. Ans. 320 rpm.

For A 5 Kw Dc Motor The Number Of Slots Per Pole Should Be

9. A 10 HP, 230V DC shunt motor hasan armature resistance of 0.5 ohm and field resistance of 115 ohm. At no loadthe rated speed is 1200 rpm and the armature current is 2 ampere. If the loadis applied the speed drops to 1100 rpm. Determine the armature current and theline current.

Ans: Ia = 40.16 A, IL = 42.16 A

10. A DC shunt machine connected to230 V DC supply has resistance of armature as 0.115 Ω and of field winding as115 Ω. Find the ratio of the speed as generator to the speed as a motor withthe line current in each case being 100 A. Ans : 1.105: 1

11. A DC series motor with seriesfield and armature resistance of 0.06 Ω and 0.04 Ω respectively is connectedacross 220 V dc mains. The armature takes 40 A and its speed is 900 rpm.Determine its speed when the armature takes 75A and excitation is increased by15% due to saturation. Ans: 770 rpm.

-----------------------------------------------------------------

THREEPHASE INDUCTION MOTOR

Formula:

·Synchronousspeed Ns = rpm

·Rotor speed Nr = Ns ( 1 – s) rpm

·Slip Speed = Ns– Nr rpm

·Absoluteslip s =

·Percent Slip( %s) =

·Rotor Frequency =f ‘ = s .f Hz

·Air Gap Power Pg= Pi – Stator Loss

·Rotor copper loss= s. Pg

·Mechanical powerdeveloped in rotor Pm = Pg (1 – s)

·Output power Po = Pm – Mechanical loss

·BHP = HP

·Total Stator Input Pi =

Where VL =Line Voltage, I L = Linecurrent , cos Ф = power factor

·Efficiency

--------------------------------------------------------------

1. A threephase, 50 Hz induction motor has a full load speed of 960 rpm. Calculate i) slip ii) number of poles iii) frequencyof rotor induced emf

iv) speed of rotor field with respect to rotorstructure v) speed of rotor field with respect to stator field vi) speed ofrevolving magnetic field in the air gap (synchronous speed) Ans: 4%, 6, 2Hz, 40rpm, 1000rpm, 1000rpm

2. A 20 HP, 440V, 50Hz 3 - phaseinduction motor works on 50 Hz supply. Determine i) speed of revolving magneticfield ii) motor speed at a slip of 5% iii) frequency of current in rotorcircuit when slip is 7.5% iv) speed of revolving magnetic field with respect torotor when slip is 4. 5%.

Ans: i) 1500 rpm ii) 1425 rpm iii) 3.75Hz iv) 1440rpm

3. The rotor of a 3- phase 6 - poles,400V, 50 Hz induction motor alternates at 3 Hz. Compute the speed and % slip ofthe motor. Find the rotor Cu loss per phase if the full load input to the rotoris 111.9 KW.

Ans: Speed Nr = 940 rpm, % slip = 6%, Rotor Cu loss per phase =2.238KW

4. The power input to a 500V, 50Hz, 6-poles,3- phase squirrel cage induction motor running at 975 rpm at 40 KW. The statorlosses are 2KW. Calculate

i) slip ii) rotor cu loss iii) BHP iv) efficiency.

Ans: % slip = 2.5%, Rotor Cu loss = 0.95KW, BHP = 47.88 HP

Efficiency = 92%,

5. A 440V, 6- poles, 50Hz, 3-phaseinduction motor develops 20KW including mechanical loss when running at 980rpm. The power factor being 0.85 lag. Calculate i) slip ii) rotor frequency iii)total stator input if stator losses are 1500 Watts iv) line current

Ans: % slip = 2%, Rotor Frequency =1Hz, Total stator input = 20.9KW

Line current = 37.2A

6. A 6 poles, 50 Hz, 500V, 50Hz, 3 -threephase induction motor running on full load with 4% slip develops 14. 92 KW withpower factor being 0.86 lag. The friction and windage losses are 200 W andstator copper and stator iron losses amounts to 1620 W. Calculate i) rotorcopper loss ii) efficiency

iii) line current iv) rotor frequency.

Ans: Rotor Cu loss = 620 W, Efficiency = 85.7%, Line current= 23.04A

Rotor Frequency = 2Hz

7. A 3-phase, 6-poles induction motordevelops 30HP including 2HP mechanical loss at a speed of 950 rpm on 550V, 50Hzmains. The power factor being 0.88 lag. Calculate i) slip ii) rotor copper loss iii)total stator input if stator losses are2KW iv)line current v) motor output

vi) efficiency.

Ans: % slip= 5%, Rotor Cu loss = 1.177K W, Total stator input = 25.55KW,

Line current = 30.41A, Motor output = 20.88 KW, Efficiency = 81.7%,

8. A 3- phase delta connected 440V,50 Hz, 4 pole induction motor has a rotor standstill emf per phase of 130 V. Ifthe motor is running at 1440 rpm. Calculate i) the slip ii) the rotorfrequency iii) the value of the rotorinduced emf per phase iv) stator to rotor turns ratio.

Ans: i) % slip = 4% ii) 2Hz iii) 5.2V/phase iv) 3.38:1

9. The power input to rotor of 440 V,50 Hz, 3- phase, 6- pole induction motor is 50 KW. The rotor emf makes 120cycles per minute. Stator iron and stator copper losses are 1KW and frictionand windage losses are 2KW respectively. Calculate i) slip ii) rotor speed iii) rotor cu loss

iv) Mechanicalpower developed v) output torque

Ans: % slip= 4%, Rotor speed = 960 rpm, Rotor Cu Loss =2KW, Mechanical Power Developed =48KW, Output torque = 457.80Nm

10. A 3 - phase, 50 Hz, 50 KWinduction motor has an efficiency of 90% at rated output. At this load thestator cu loss, the rotor cu loss & stator core loss are equal. Thefriction and windage loss (mechanical loss) is equal to one third of the statorcore loss. Calculate i) rotorcu loss ii) airgap power iii)slip

Ans : i) 1665W ii) 52220W iii) 0.031 (3.1%)

11. The power input to the rotor of a 400V, 50Hz, 6-pole, 3 - phase induction motor is 75KW. The rotor electromotive force isobserved to make 100 complete alternations per minute. Calculate i) slip ii) rotor speed

iii) rotor cu losses per phase iv) mechanical power developed v) therotor resistance per phase if the rotor current is 60 A

Ans: i) 3.3% ii)967rpm iii)825W iv) 72.525KW v) 0.23 Ω

12. The shaft torque or useful torqueof a three phase, 50 Hz, 8 pole induction motor is 190Nm. If the rotorfrequency is 1.5Hzand mechanical losses are 700 Watts, Calculate i) slip ii) power output iii) mechanical power developed iv) rotor copper loss

Ans: 3%, power output = 14474.9 W

mechanical power developed =15174.9W, rotor copper loss = 469.326W

13. An induction motor is running atfull load and develops a torque of 180 Nm when the rotor makes 120 revolutionsper minute. If number of poles be 4 and supply frequency is 50 Hz, calculatethe shaft power.

Ans: shaftpower = 27.13KW.

14. Thepower input of a three phase induction motor is 90 KW. Find the mechanicalpower developed if the stator losses are 1.5 KW. Also find the rotor copperloss. It is given that slip of the induction motor is 3%.

Ans:mechanical power developed = 85.845 KW,

Rotor copperloss = 2.655KW

THE END

What is the maximum number of circuit breakers allowed in an electric panel?

Saturday, June 16, 2018

Not What It Used To Be

The answer to this question was once very simple. The National Electrical Code (NEC) specified that a lighting and appliance branch circuit panelboard could not contain more than 42 overcurrent devices (circuit breakers). That was the absolute maximum, unless the manufacturer specified a lower number, which was often the case for smaller panel boxes.

But the 2008 edition of the NEC deleted the maximum number and the new standard became whatever the manufacturer specifies. That number can be found in the fine print of the data plate on the inside of the panel door and is often near the schematic diagram. Some panels only allow one breaker per slot, while others allow some or all of the slots to accept a tandem breaker, which fits two breakers in one slot. So a “20/30” panel, for example, has 20 slots, but will accept up to 30 circuits, allowing up to half of the slots to be tandems.

CTL Breakers Also Important

The NEC has had an additional requirement since 1965 that “a panelboard shall be provided with a physical means to prevent the installation of more overcurrent devices that than that number for which the panelboard was designed, rated, and listed.” This is known as Circuit Total Limitation panel or “CTL.” Unfortunately, non-CTL breakers are still manufactured for repair of pre-1965 panels, and are sometimes used in newer panels to get around this limitation. They lack the “rejection” feature that keeps CTL-breakers from being installed improperly. Both CTL and non-CTL breakers are clearly marked, although in very fine print, on the side of the breaker.

Maximum Amps Per Stab

One additional limitation for the breakers in a panel is the “maximum amps per stab” that a manufacturer allows. A stab is another name for a bus bar finger. Panels have half as many stabs as total breaker slots, so a panel with forty slots has twenty stabs, and a typical 150-amp rated panel requires that the sum of the amperages of both the breakers on one bus bar finger not exceed 200 amps. So this means you cannot have two breakers side-by-side with a total amp rating that exceeds 200 amps. This maximum is also listed in the data plate, which may also list limits on the number, rating, or arrangement of the breakers in the panel. To learn more, see our blog post What is a 'bus stab' in an electric panel?

So the short answer to the maximum number of breakers question is 42 for pre-2008 panels, and whatever the manufacturer specifies for newer panels—while not exceeding the maximum amps per stab or using non-CTL breakers in a CTL panel.

Also, see our blog posts Should I buy a house near a high-voltage power line? and What causes copper wires to turn green or black in an electric panel? and Can you add circuit breakers by different manufacturers to an electric panel if they fit?

• • • • • • • • • • • • • • • • • • • • • • • • • • • •

Here’s links to a collection of our other blog posts about ELECTRIC PANELS:

• My circuit breaker won't reset. What's wrong?

• What is a split bus electric panel?

• What is the maximum number of circuit breakers allowed in an electric panel?

• When should a corroded or damaged electric panel cabinet or disconnect box be replaced?

• What is a tandem circuit breaker?

• When did arc fault circuit interrupter (AFCI) breakers first become required?

• Can an electric panel be located in a closet?

• Can an electric panel be located in a bathroom?

• How do I identify a combination AFCI (CAFCI) circuit breaker?

• What does a circuit breaker with a yellow or white test button indicate?

• What is the maximum gap allowed between the front of a recessed electric panel box and the wall surface surrounding it?

• What are the requirements for NM-cables entering an electric panel box?

• Why is a fuse box/panel an insurance problem for homebuyers?

• Why is bundled wiring in an electric panel a defect?

• What is the difference between GFCI and AFCI circuit breakers?

• Why are old electrical components not always 'grandfathered' as acceptable by home inspectors?

• What happens when you press the 'TEST' button on a circuit breaker in an electric panel?

The Number Of Slots Per Pole Should Be Paid

• What is a Dual Function Circuit Interrupter (DFCI)?

• What is the difference between a Combination Arc Fault Circuit Interrupter (CAFCI) and an Arc Fault Circuit Interrupter (AFCI) circuit breaker?

• What is the difference between 'grounded' and 'grounding' electrical conductors?

• What does it mean when a wire is 'overstripped' at a circuit breaker?

• Why is an old fuse panel dangerous?

• Who is the manufacturer of those 'bad' electric panels?

• Why is the circuit breaker stuck in the middle?

• What is a double tap at a circuit breaker?

• What is the right electric wire size for a circuit breaker in an electric panel?

• What is the life expectancy of a circuit breaker?

• My circuit breaker won't reset. What's wrong?

• Why do some breakers in my electric panel have a 'TEST' button on them?

• What is the right size electric panel for a house?

• What do I need to know about buying a whole house surge protector?

• What is the maximum allowed height of a circuit breaker (OCPD) above the floor?

• What is the maximum height you can mount an electric panel above the floor?

• What is the code required clearance in front of an electric panel?

• What is the main bonding jumper and where do it find it in an electric panel?

Visit our ELECTRIC PANELS page for other related blog posts on this subject, or go to the INDEX for a complete listing of all our articles.

The Number Of Slots Per Pole Should Be Replaced

How To Look At A House

The Number Of Slots Per Pole Should Bet

McGarry and Madsen's home inspection blog for buyers of

The Number Of Slots Per Pole Should Beams

site-built, mobile/manfuactured and modular homes

Click Below

for Links

to Collections

of Blog Posts

by Subject

Top 5 results given instantly.

Click on magnifying glass

for all search results.